Optimization & Fault Prediction

(AI/ Robot Management)

At HandPhil Enertex Inc., we harness the power of artificial intelligence to optimize the efficiency, reliability, and security of solar power plants. By integrating state-of-the-art AI/ Robot monitoring and inspection technologies, we ensure that our renewable energy infrastructure operates at peak performance while minimizing operational risks and costs.

AI/ Robot Monitoring Systems

Our AI/ Robot Monitoring Systems provide real-time data analysis and automated diagnostics to enhance the performance of solar power plants. These systems leverage advanced machine learning algorithms to continuously track key performance indicators, detect anomalies, and optimize energy output.

Key features include

- Real-Time Monitoring & Analytics:

AI-powered sensors continuously collect and analyze data from solar panels, inverters, and other critical components to identify inefficiencies and optimize energy production. - Predictive Maintenance Technology

By analyzing historical performance data and system trends, our AI models predict potential equipment failures before they occur, reducing downtime and maintenance costs. - Automated Performance Optimization

The system dynamically adjusts operations based on environmental conditions such as sunlight intensity, temperature, and grid demand, ensuring maximum energy efficiency. - AI/ Robot Analytics & Autonomous Inspection Technology

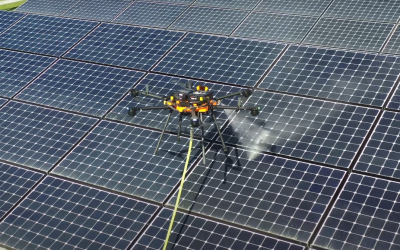

To further enhance the reliability of our renewable energy systems, HandPhil Enertex has developed AI-Powered Analytics & Autonomous Inspection Technology. This advanced system utilizes AI-driven drones and robotic inspection units to survey and diagnose solar power plants with unparalleled precision.

Key advantages include

Autonomous Aerial & Ground Inspections: AI-powered drones equipped with infrared and high-resolution cameras conduct routine inspections of solar farms, identifying panel defects, wiring issues, and structure.